Bench 01 – the design process and production

It feels weird but an airy concept of order & chaos and the highest client expectations can find the best design iteration in a discarded satellite dish …

Expressing a concept in form and material

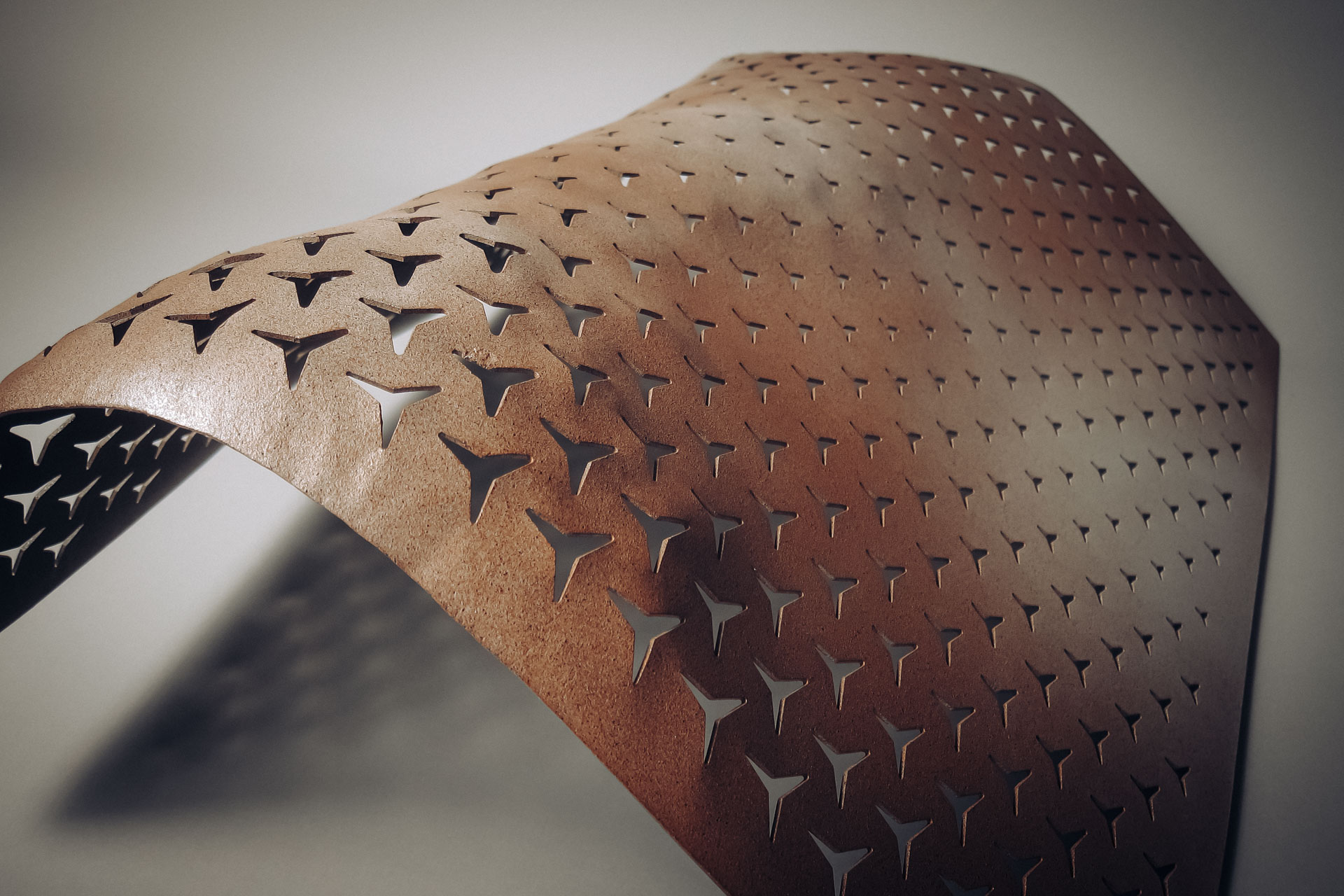

As implied above the seminal physical expression for the Bench in the early stages came from hand shaping a discarded rusty perforated satellite dish. It gave us the most convincing form and pattern interaction and really clicked with the conflicting nature of the brief. In the images it all looks so graceful and intentional, but there is a lot of random discovery in this. It is my favourite mode in the first design process phases – just act intuitively and trust the process of thinking & making. Complete small steps, record, repeat.

The beautiful interaction of the circular perforations and the 100mm f2.8 macro lens bokeh is another project’s inspiration on its own here.

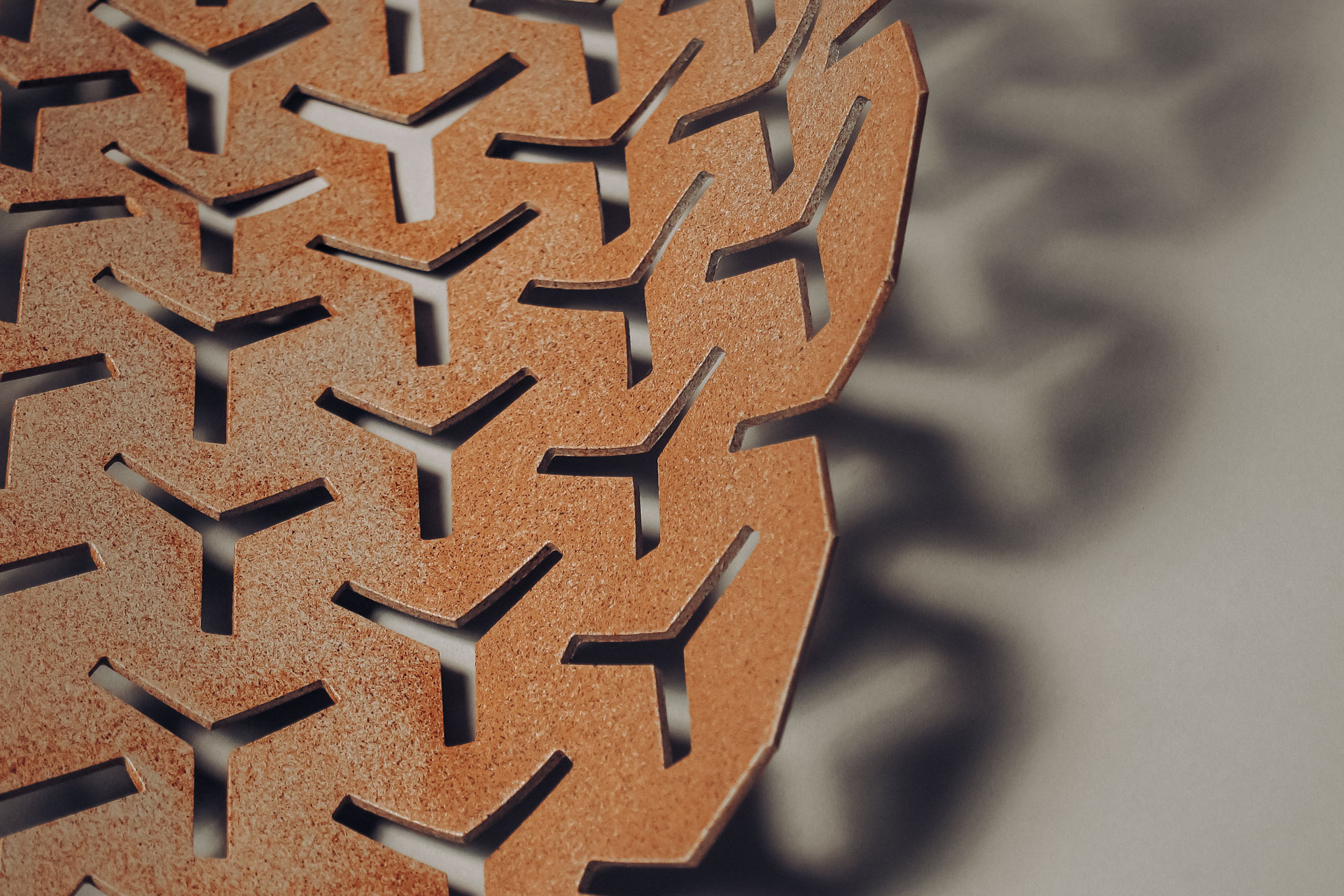

Perforation search for the 2D-to-3D transition

The relationship between a spatial form and its flat 2D counter-part takes a lot of model iterations to discover and fine-tune. I thought about this process many times afterwards contemplating if it could be done digitally. You could sculpt the form and have the dynamic perforation happen on its surface, but the unwrapping of that into flat would be very hard to achieve so that you can manufacture from the data. Besides the final 1:1 was always going to be formed by hand so it made sense to also do the development models by hand in 1:10.

This is 500 meters of laser-cutting.

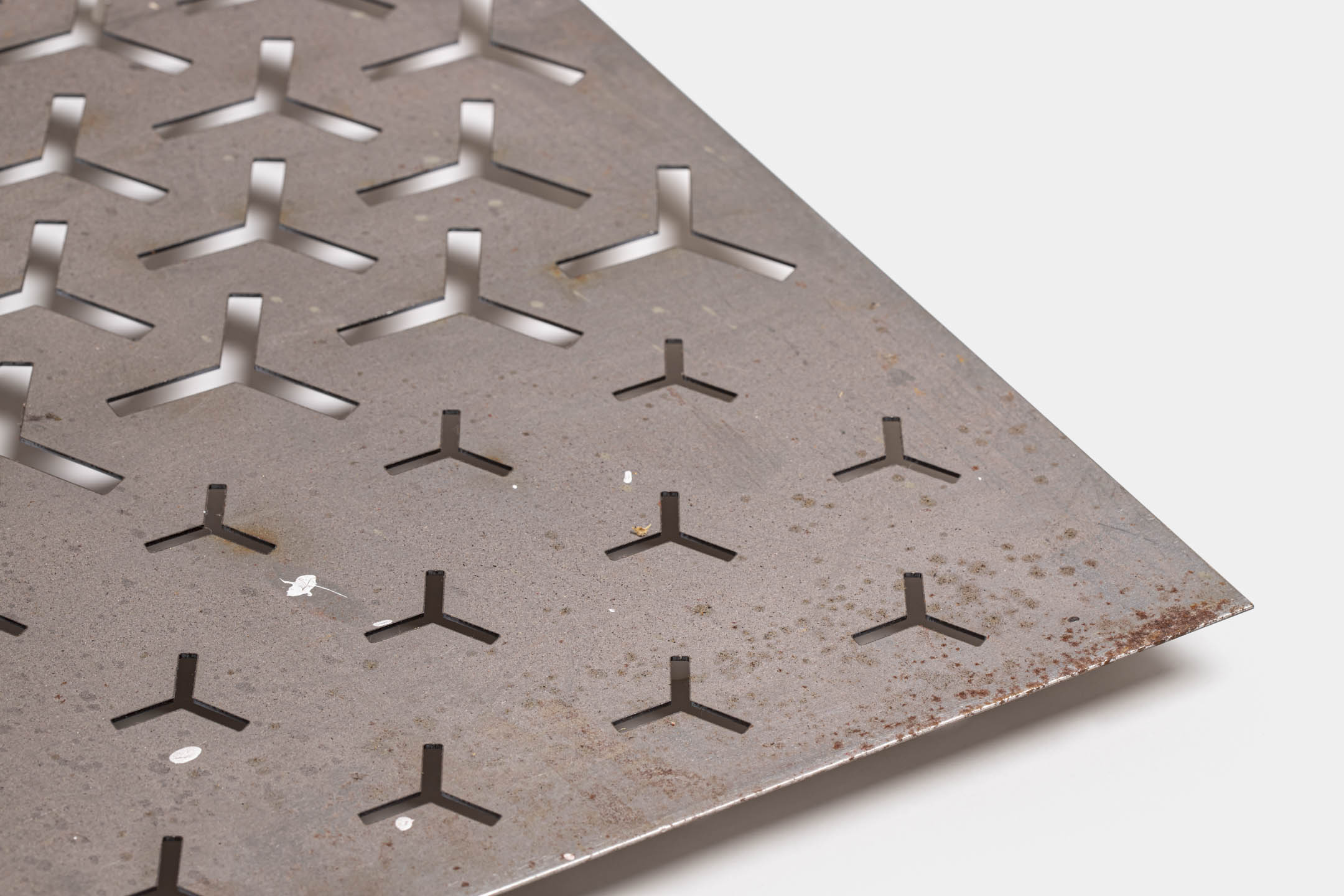

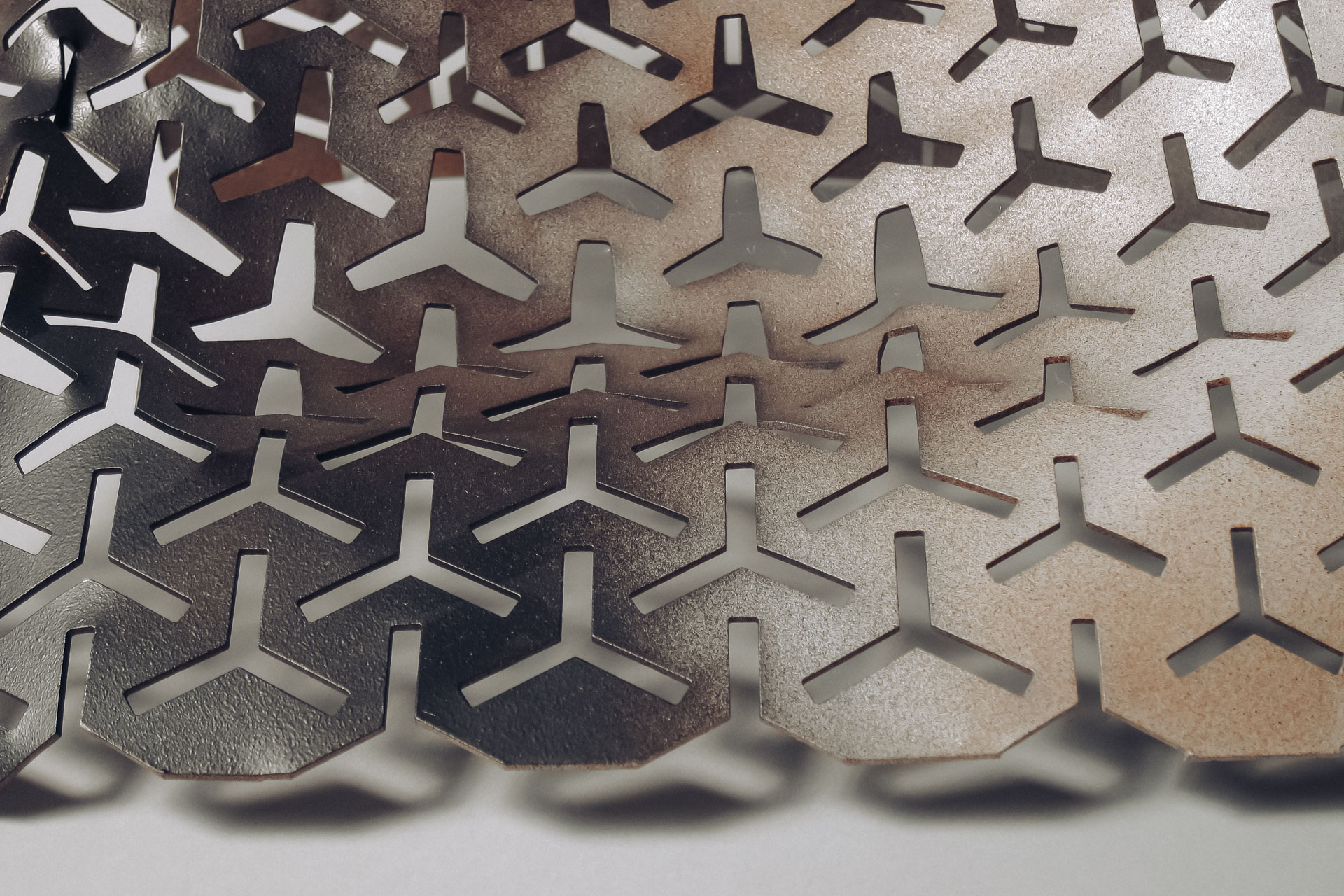

Perforation & rust exercises

On the way to formulate the right kind of perforation shape and density we created a whole series of 500 x 500 mm sample surfaces. These then underwent several processes ranging from cold bending, across heat bending, rusting in an acid bath all the way to brushing and hammering. A lot of these decisions are done very intuitively with an expectation of a result but the result is never guaranteed when you really want to discover something. It is an act of embracing of the unexpected. The final choice of surface finish for Bench 01 was influenced by the ability to predict its ageing in its environment. The active rusty surfaces are beautiful but very unpredictable for that.

The man with the two guns

So if you don’t want to leave a metal rusted, you don’t want to paint it or powder-coat it what do you do? I was really keen to find some other way to treat the surface of this remarkable form. I managed to convince the guy who sprays the static powder dust onto the metals to actually use two guns and fuse two different paints together on the surface of the metal simultaneously. This is the result and I have to say it is really amazing and also has a lot of potential. In the end we managed to find an even more unique surfacing method for the bench and this ended up unused. But it will come back in some future project for sure.

Sheet to sphere

This is not the best version of the perforation pattern as it has a wrong ratio of openings to solid surface. It is too slow in response to bending and hammering. But even here it is obvious how it is capable of forming around a spherical mold. The right kind of perforation pattern just turns a solid steel surface into a piece of fabric that adapts and conforms when using the right tools.

Metal extremes

In the weeks leading up to the production of Bench 01 there were many tests done to see how the perforated metal responds to heat and what combination of techniques to use to get the desired shape. We ended up working with a combination of local gas flame heating and cold oil forging. This technique allows to shape the surface while increasing the strength of the metal in the forged areas. It gives the bench a balance of soft comfortable bounciness and structural strength.

Traditional blacksmith techniques in test.

The 1.5 mm steel sheet just before laser-cutting. There is no standard sheet in the needed size so we ended up welding two sheets together carefully to create a smooth surface that works in the laser-cutter.

Project info

Products & Objects

Client

Private client

Creative direction, design, ideation, product development, 2D & 3D modelling, material technologies, prototyping

Matej Chabera

Collaboration

Jeana Schmücking

Development & production

Chabera Studio in collaboration with expert blacksmith and locksmith Vladimír Sailer and other technological companies and craftsmen, produced in Czechia

Photography

Chabera studio

Year

2010 – 2011